Industrial Robotics 1st Module

Automation and robotics

Automation – It is a technology that is concerned with the use of mechanical electronic and computer-based systems in the operation and control of production.

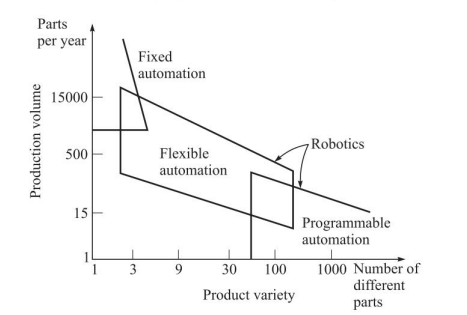

There are three broad classification of industrial automation -

· Fixed Automation

· Programmable automation

· Flexible automation

Fixed Automation - Fixed automation is used when the volume of production is very high and it is, therefore, appropriate to design specialized equipment to process the product (or a component of a product) very efficiently and at high production rates

The economics of fixed automation are such that the cost of the special equipment can be divided over a large number of units and the resulting unit costs arc low relative to alternative methods of production.

The risk encountered with fixed automation is that since the initial investment cost is high, if the volume of production turns out to be lower than anticipated, then the unit cost become greater than anticipated.

Another problem with fixed automation is that the equipment is specially designed to produce the one product and after that product’s life cycle is finished, the equipment is likely to become obsolete. For products with short life cycle, the use of fixed automation represents a big gamble

A good example of fixed automation can be found in the automobile industry, where highly integrated transfer lines consisting of several dozen workstations are used to perform machining operations on engine and transmission components.

Programmable Automation - Programmable automation is sued when the volume of production is relatively low and there are a variety of products to be made. In this case, the production equipment is designed to be adaptable to variations in product configuration.

This adaptability feature is accomplished by operating the equipment under the control of a “program” of instructions which has been prepared especially for the given product.

The program is read into the production equipment, and the equipment performs the particular sequence of processing (or assembly) operations to make the product.

In terms of economics, the cosy of the programmable equipment can be spread over a large number of products even though the products are different. Because of the programming feature and the resulting adaptability of the equipment, many different and unique products can be made economically in small batches

Flexible Automation

It is also known as “flexible manufacturing systems and “computer integrated manufacturing systems”. The concept of flexible automation has only developed into practice within the past 15 or 20 years.

Experience thus far with this type of automation suggests that it is most suitable for the mid volume production range as it can be seen in figure above

Flexible systems possess some of the features of both fixed automation and programmable automation. It must be programmed for different product configuration, but the variety of configuration is usually more limited than programmable automation, which allows a certain amount of integration to occur in the system.

Flexible automated systems typically consist of a series of workstation that are interconnected by a materials- handling and storage system. A central computer is used to control the various activities that occur in the system, routing the various parts to the appropriate stations and controlling the programmed operations at the different stations.

One of the features that distinguish programmable automation from flexible automation is that with programmable automation, the products are made in batches. When one batch is completed, the equipment is reprogrammed to process the next batch.

With flexible automation, different products can be made at the same time on the same manufacturing system. This features allows a level of versatility that is not available in pure programmable automation.

Robotics – the branch of technology that deals with the design, construction, operation, and application of robots

Or

Robotics is a form of industrial automation

An industrial robot is a general purpose, programmable machine which possesses certain anthropomorphic or human-like characteristics. The most typical human-like characteristic of present day robots is their movable arms.

The robot can be programmed to move its arm through a sequence of motions in order to perform some useful task. It will repeat that motion pattern over and over until reprogrammed to perform some other task.

Hence the programming feature allows robots to be used for a variety of different industrial operations, many of which involve robot working together with other pieces of automated or semi-automated equipment.

Operations include machine loading and unloading, spot welding spray painting etc

Official definition of an industrial robot provided by robotics industries association (RIA) -

An industrial robot is a reprogrammable, multifunctional manipulator designed to move materials, parts, tools or special devices through variable programmed motions for the performance of a variety of tasks.

Robots can be classified into

· industrial robots

· Service robots

An industrial robot is essentially a manipulator arm used mainly in the automobile industry for automation.

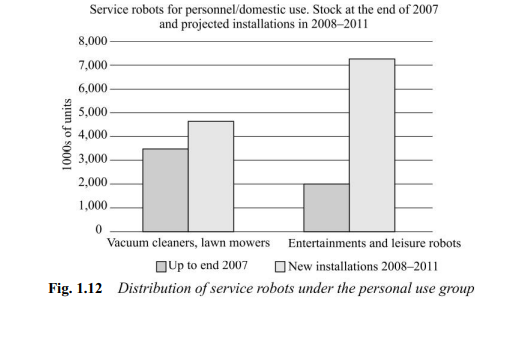

While service robots are those that operate autonomously to perform services useful to the well being of humans and equipment.

Service robots are further classified into robots used for personal use in homes such as vaccum cleaner, lawn mower etc.

Robotics in Science fiction

Notwithstanding the limitation of current day robotic machines, the popular concept of a robot is that it looks and acts like a human being. This humanoid concept has been inspired and encouraged by a number of science fiction stories.

Certainly one of the first works of relevance in discussion of robotics in the science fiction novel by Mary Shelley titled Frankenstein in 1817, the story deals with the efforts of a scientist Dr, Frankenstein, to create a humanoid monster which them proceeds to raise havoc in the local community

A Czech play in the early 1920s by Karel Capek called Rossum’s Universal Robots, gave rise to the term Robot. The Czech word “robota”means servitude or forced worker and when translated into English, the word becomes robot.

The story concerns a brilliant scientist named Rossum and his son who develop a chemical substance that is similar to protoplasm. They use the substance to manufacture robots. Their plan is that the robots will serve humankind obediently and do all physical labour. The plot takes a sour turn when the perfect robots begin to dislike their subservient role and proceed to rebel against their masters, killing all human life.

Among science fiction writers, Isaac Asimov has contributed a number of stories about robot starting in 1937 and is credited with coining the term “robotics”. The robots that appear in his work is that of a well-designed fail safe machine that performs according to three principles.

These principles were called three laws of robotics by Asimov and they are

1. A robot may not injure a human being or through inaction, allow a human to be harmed

2. A robot must obey orders given by human except when that conflicts with the first law.

3. A robot must protect its own existence unless that conflicts with the first or second laws.

It is interesting to note that in real world, industrial robots obey laws that are opposite of the one stated above! A robot may injure a human, it may not obey humans and it also may not protect its own existence.

As robotics technology advanced so did the appearance of robots in movies as seen in terminator series, matrix series, and transformer series etc. In these movies robots seem to stretch our imagination about life, death rebirth and reality. Advancement in software technology has come to a stage that in movies it is now difficult to distinguish a real person from a virtual character!

Numerical control and telecherics

Numerical control and telecherics are two important technologies in the development of robotics.

Numerical control (NC) was developed for machine tools in the late 1940s and early 1950s. As its name suggests, numerical control involves the control of the actions of a machine tool by means of numbers. It is based on the original work of John Parsons who conceived of using punched cards containing position data to control the axes of a machine tool. He demonstrated his concept to the United States Air Force, which proceeded to support a research and development project at the Massachusetts institute of Technology.

The MIT project used a three axis milling machine to demonstrate the prototype for NC in 1952. Subsequent work at MIT led to the development of APT (Automated Programmed Tooling), a part programming language to accomplish the programming of NC machine tool.

The field of telecherics deals with the use of a remote manipulator controlled by a human being. Sometimes called a tele-operator, the remote manipulator is a mechanical device which translates the motions of the human operator into corresponding motions at a remote location.

A common use of a tele operator is in the handling of dangerous substances, such as radioactive materials.The human can remain in a safe location; yet by peering through a leaded glass window or by viewing on closed-circuit television, the operator can guide the movements of the remote arm.

Early telecheric devices were entirely mechanical, but more modern systems use a combination of mechanical systems and electronic feedback control.

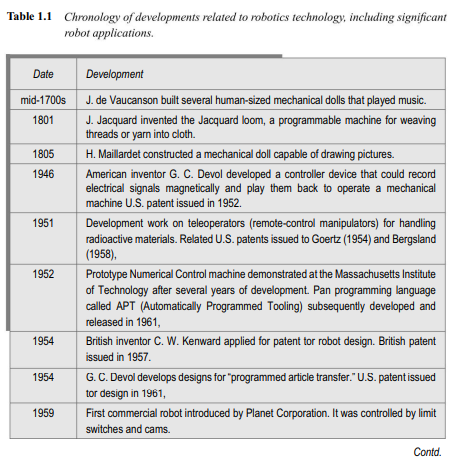

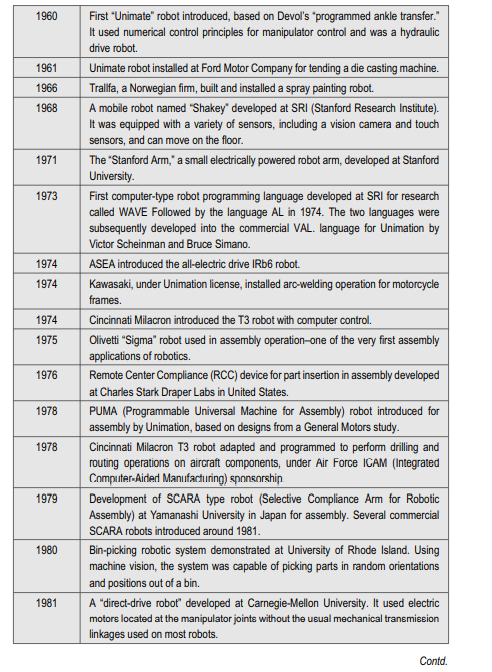

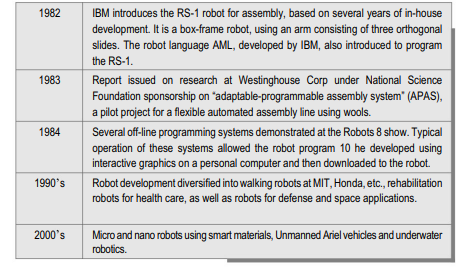

A Brief History of Robotics

Science fiction has no doubt contributed to the development of robotics, by planting ideas in the minds of young people who might embark on careers in robotics and by creating awareness among the public about this technology. Table presents a chronological listing which summarizes the main early historical developments in the technology of robotics.

Until the early 1940s most of the automation devices mentioned above were not really programmable, in the way we understand by the word program. Birth of programmable automation or soft automation took place with the development of the microprocessor in late 1940. It was now possible to easily change the program controlling an automation device. Robot development went through the following phases from 1950 to 2010:

1950 – Late 1970: Simple pick and place robots controlled by a large computer with limited interaction with the environment (confined to the manufacturing industry for hazardous and repetitive jobs).

1980 – Late 1990: Interaction with the environment using force, touch sensors, visions etc (due to development of cheaper electronics)

1990-2000: Intelligent robots (due to higher computing power, smaller and lighter on-board processors, smart actuators, sensors)

2000 – Present: micro Nano robots, bio-robots, humanoids, service robots etc. (Interest in emulating biological design paradigms and a gradual shift from only industrial applications to humanitarian applications).

Future robots: personal robots, professional robots (newer application in drug delivery, surgery, rehabilitation, caretaker etc.)

The robotics market and the future prospects

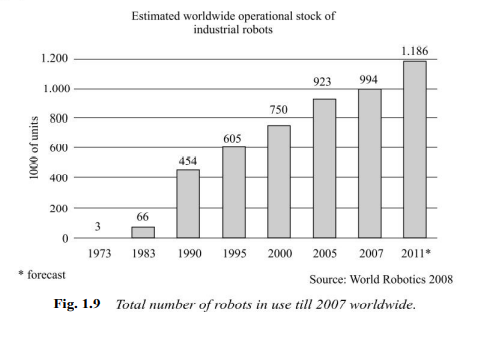

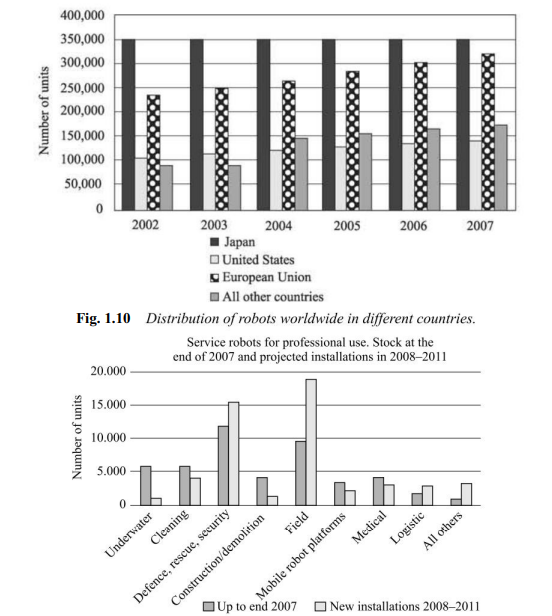

Annual sales of robots have been growing worldwide and the latest total robot population worldwide is given in fig below. Traditionally it was the automotive industries that led the drive to robotize, however, in the last decade, the growth of non-automotive robots has higher than automotive robots.

There are several reasons for the surge of robotics investments: one of which is the fall in robot prices as compared to the increase in labour costs. At the same time, today’s robots have better performance in terms of accuracy, speed, versatility and above all, computer power as compared to earlier robots. Other factors that would force industries to robotize is the shrinking of the work force in several developed countries and an ageing population

Industrial Robotics Market from US$45 billion in 2020 to US$119 billion by 2030

The robotics market offers a diverse and ever-expanding selection of items. After many years of partnership with both eastern and western consumers, predictions about the future progress of automation and the robotics industry are plausible. The growing need to automate more and more online food operations has increased the employment of robotic technology in these domains.

Effect of Covid 19 on Robotics Market

The covid-19 effect is expected to increase the scale of the Industrial Robotics Market from US$45 billion in 2020 to US$119 billion by 2030. Over the projected period of 2020 to 2030, it is expected to grow at a CAGR of 15%. The 2025 forecast is predicted to be roughly 3% lower than the pre-COVID-19 prediction. The key driving drivers for the business are a lack of qualified labour and government and public-private partnerships presenting suggestions to mitigate the negative consequences of COVID-19.

While the COVID-19 epidemic dampens market development until the second and third quarters of 2020, the market is likely to rise from 2021 onwards as firms in the industrial robotics industry clear their bottlenecks and resume accepting new orders. In the year 2019, KUKA’s business segment Robotics (Germany) had order bottlenecks totaling US$309 million (EUR 276 million).

Collaborative robots are becoming increasingly popular

Collaborative robots enable humans and robots to work effectively together in open or uncaged environments. It is feasible to include a human operator and a bot in the same operation by using collaborative robotics. The standards for the design of robotic systems are described in ISO 10218 and ISO / TS 15066 technical specs. Collaborative robots are designed to be safe, with no possibility of damage or interruption. The lack of cages reduces the amount of room required to deploy the robots. Collaborative robots have grown more approachable and manageable for unskilled users.

High deployment costs for small and medium-sized businesses

A robot automation program can be intimidating, especially for firms that have never used one before. High capital expenditures are required not only for robot purchase, but also for setup, programming, and maintenance. In some circumstances, a specialised implementation may be necessary, increasing the overall cost. Companies may not always have the necessary services and capability to deploy robots. Because small and medium-sized businesses often produce in small quantities, return on investment (ROI) may be an issue. The presence of businesses with seasonal or variable production schedules exacerbates the problem. Rapidly changing customer tastes would necessitate regular retraining of robots, as goods must be changed on a yearly basis. Cost overruns occur as product lines and market potential change substantially over time, rendering many units redundant or obsolete. Over-automation can also be problematic.

Increasing automation in the electronics industry

For some years, the automobile industry has been the main buyer of robots for manufacturing tasks. The balance of power is rapidly shifting. According to estimations, the growth of the electronic industrial robotics industry has surpassed that of the automotive industry. Despite expanding profit margins, robot automation is expected to be a successful notion for the electronics industry in the next years. Customization is becoming the norm in this industry.

In short, future robots will have many of the attributes of human beings. Getting from the present to the future will require much work in mechanical engineering, electrical engineering, computer science, industrial engineering, materials technology etc.