Material Science 5th Module

Module 5

Smart Materials

Piezoelectric material

Piezoelectric Material uses the application of piezoelectricity that accumulates in certain solid materials in response to mechanical stress

The word piezoelectricity means electricity resulting from pressure and latent heat

The piezoelectric effect is a reversible process: materials exhibiting the piezoelectric effect(the internal generation of electrical charge resulting from an applied mechanical force) also exhibit the reverse piezoelectric effect, the internal generation of a mechanical strain resulting from an applied electrical field.

Mechanism or working principle

• The nature of the piezoelectric effect is closely related to the occurrence of electric dipole moments in solids.

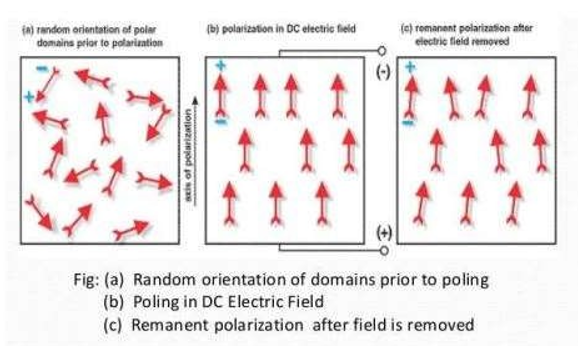

• The domains are usually randomly oriented, but can be aligned using the process of poling

• Piezoelectric effect is the change of polarization P when applying a mechanical stress. This might either be caused by a reconfiguration of the dipole-inducing surrounding or by re-orientation of molecular dipole moments under the influence of the external stress.

• Piezoelectricity may then manifest in a variation of the polarization strength, its direction or both, with the details depending on:

1. The orientation of P within the crystal

2. Crystal symmetry

3. The applied mechanical stress Different types of piezoelectric materials are

Natural – Quartz, Rochelle Salt, Topaz Surcose etc

Synthetic – Zinc oxide (ZnO), Lead zincronite tinate (PZT) , Barium Titanite (BaTiO3) etc

Applications –

Piezoelectricity is exploited in a number of useful applications, such as the

• Production and detection of sound

• Piezoelectric inkjet printing,

• Generation of high voltages

• Clock generator in electronics, Microbalances,

• To drive an ultrasonic nozzle, and ultrafine focusing of optical assemblies.

Magneto strictive materials (Magnetostriction)

Magnetostriction is a property of ferromagnetic materials which causes them to expand or contract in response to a magnetic field.

This effect allows magnetostrictive materials to convert electromagnetic energy into mechanical energy.

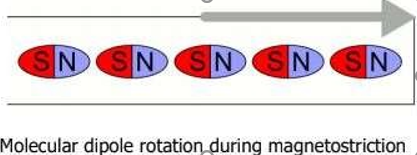

As a magnetic field is applied to the material, its molecular dipoles and magnetic field boundaries rotate to align with the field. This causes the material to strain and elongate

• Magnetostrictive materials are used to convert electromagnetic energy into mechanical energy and vice versa. This effect can be used to create sensors that measure a magnetic field or detect a force. The magnetic field or force applied would create a strain in the material, which can be measured.

• Transformers also use mangnetostrictive materials in conjunction with Faraday's law to convert magnetic fields into an electromotive force. During this process, the change in magnetic flux is converted into an electromotive force (EMF) in the transformer.

This effect is used to increase or decrease AC voltages and to transfer them from one circuit to another. When exposed to a changing magnetic field (wave) the magnetostrictive material responds by rotating

its molecular dipoles in phase with this frequency. The maximum change in length of the material occurs twice per period of the magnetic field. This results in a humming sound, which is commonly heard from transformers.

Applications

A changing magnetic field can also be used in conjunction with magneto-strictive materials to produce vibrations. Such materials are used in

• medical devices and industrial vibrators

• ultrasonic cleaning devices

• underwater sonar

• vibration or noise control systems, and in many other applications.

Similarly, magnetostrictive transducers can be used to transfer ultrasonic energy into other materials.

Electrostructive Material

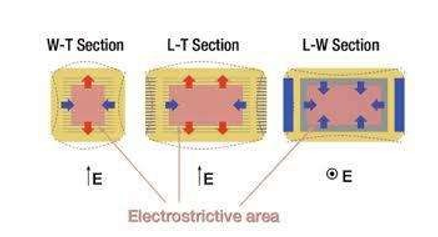

• Electrostriction is a property of all dielectric materials, and is caused by displacement of ions in the crystal lattice upon being exposed to an external electric field.

• Positive ions will be displaced in the direction of the field, while negative ions will be displaced in the opposite direction.

• This displacement will accumulate throughout the bulk material and result in an overall strain (elongation) in the direction of the field.

• The thickness will be reduced in the orthogonal directions characterized by Poisson's ratio.

• All insulating materials consisting of more than one type of atom will be ionic to some extent due to the difference of electronegativity of the atoms, and therefore exhibit electrostriction.

• The resulting strain (ratio of deformation to the original dimension) is proportional to the square of the polarization. Reversal of the electric field does not reverse the direction of the deformation.

Materials

Although all dielectrics exhibit some electrostriction, certain engineered ceramics, known as relax or ferroelectrics, have extraordinarily high electrostrictive constants. The most commonly used are

• lead magnesium niobate(PMN)

• lead magnesium niobate-lead titanate (PMN-PT)

• lead lanthanum zirconate titanate (PLZT)

Applications

• Sonar projectors for submarines and surface vessels

• Actuators for small displacements

Magnetorheological fluids

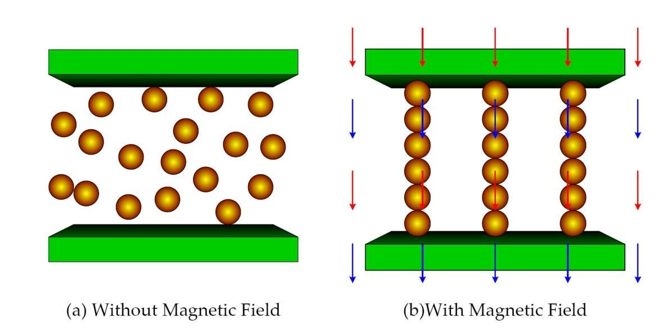

A magnetorheogical fluid is a type of smart fluid in a carrier fluid, which is when under an influence of a magnetic field, the fluid greatly increases its apparent viscosity, to the point of becoming a viscoelastic fluid

MR fluid is a type of rhelogical fluid whose yield stress can be varied by an applied magnetic fluid.

A typical MR Fluid consists of micron sized magnetizable iron/ferrous particles suspended in a base fluidlike silicone oil or water

Functions of MR fluids

1. These are liquids that change their properties when we apply a magnetic field to them

2. When the magnet is in place the MR fluid turns into solid

3. When the magnet is removed the solid is instantly revertsto liquid

Constituents of MR Fluid

· Carrier Oil

1. Parafin Oil

2. Silicon oil

3. Water

· Additives

1. Grease

2. Arabic Gum

· Magnetic Particles

1. Iron Particles

2. Nickel

Application of MR fluid

1. Dampers

2. Shock absorbers

3. Rotary brakes

4. Clutches

5. Prosthetic devices

6. Polishing devices

7. Polishing and grinding devices

8. Semiactive control devices

Electrorheological (ER) fluid

The characteristics of an electrorheological (ER) fluid, as a class of smart soft matter, can be actively and accurately tuned between a Liquid- and a solid-like phase by the application of an electric field.

ER materials used in ER fluids are electrically polarizable particles.

Properties of ER Fluid

In ER fluids, the carrier liquids should have high electrical resistivity and low viscosity, while the particles are commonly metal oxides, alumina, silicates, silica, organics or polymers, which could be electrically polarized.

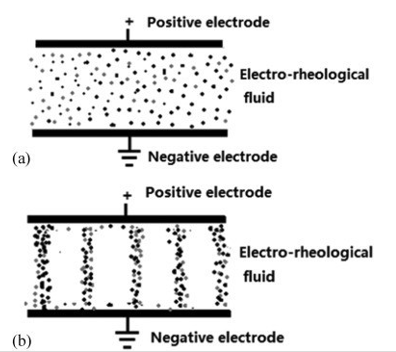

As shown in Fig. 1(a), if the ER fluid is free of electric field, the particles are distributed uniformly in the fluid and it can flow as a Newtonian fluid with viscosity µ. However, when subjected to a highly intensive electric field, whose intensity could be up to 5 kV/mm, the particles will form a chain-like structure parallel to the electric field direction as shown in Fig. 1(b).

As a result, the flowing resistance or apparent viscosity can be controlled by the intensity of the electric field. Upon the removal of electric field, the original properties of the ER fluids could be recovered.

Applications

1. The normal application of ER fluids is in fast acting hydraulic valves and clutches,

2. It is used inER Brakes

3. It is used inshock absorber

Shape Memory Alloys (Materials)

Shape memoryalloys (Materials) are the materials that remember theiroriginal shape. If deformed they can recover their original shape upon heating. They can also take large stress without undergoing permanent deformation.

They can be formedinto various shapeslike bars, wires,plates and rings thus serving various functions

Working principle

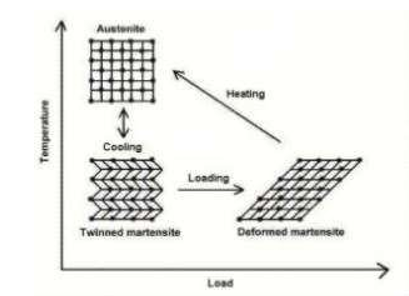

· A molecular rearrangement in the shape memory alloys (materials) austenite phase is responsible for its unique properties

· Martensite is relatively soft and occurs at lower temperatures

· Austenite occurs at higher temperature.

· The shape of austenite structure is cubic

· The un-deformed Martensite phase is the same size and shape as the cubic austenite phase on a macroscopic scale

· No change in size or shape is visible in shape memory alloys until martensite is deformed

· To fix the parent shape, the metal must be held in position and heated to about 500° C

· The high temperature causes the atoms to arrange themselves into the most compact and regular pattern possible resulting in a rigid cubic arrangement (austenite phase)

Applications

1. Reinforcement -Shape memory alloy are particularly beneficial for construction in seismic regions

2. Bolted Joints – Shape memory alloy material can be employed in beam column and column foundation joints to reduce their vulnerability by dissipating greater energy through larger plastic deformation and then recovering it on removal of load

3. Prestressing -Shape memory alloy strands are used in pre tensioning and post tensioning, Also Shape memory alloy in prestressing have the potential for creating smart structure

4. Restrainers – By use of shape memory alloy restrainers we can overcome the limitations of unseating as they have large realistic strain range and can be brought back to its original position even after deformation.