PLC AND SCADA 3RD MODULE

Definition and Classification of a timer

A timer is a device that introduces a time delay in a circuit or a system during its ON or OFF condition. Timers can be classified as follows:

(i) Electromechanical timers, (ii) Electronic timers (iii) PLC timers

An electromechanical timer uses an oil dashpot or a spring to introduce a time delay as soon as an electrical signal initiates it. An electronic timer uses an electronic circuit for incorporating a time delay and in a PLC timer, the time delay is introduced by programming.

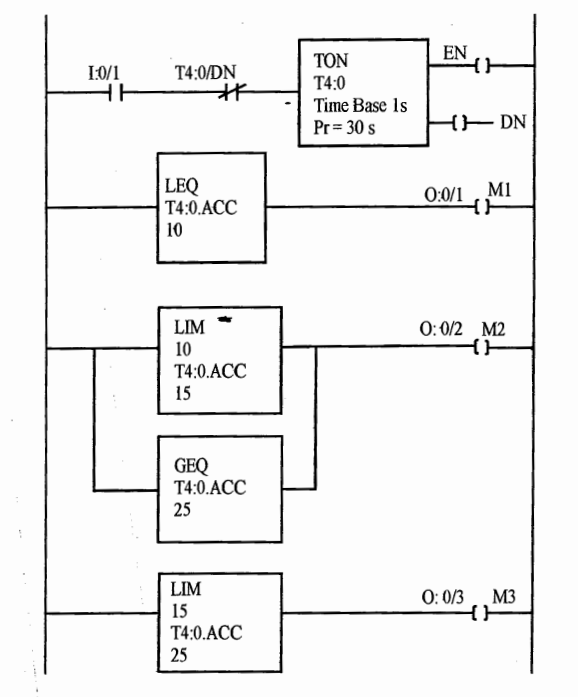

Classification of a PLC timer

As shown in fig there are two types of delay timers i.e ON Delay Timer and OFF delay Timer. If the timer contact is made ON after lapse of a certain time counted from the instant of energisation of the timer coil, that timer is called an ON delay timer. If the timer contact is made OFF after lapse of a certain time counted from the instant of de-energisation of timer coil, that timer is called an OFF delay timer.

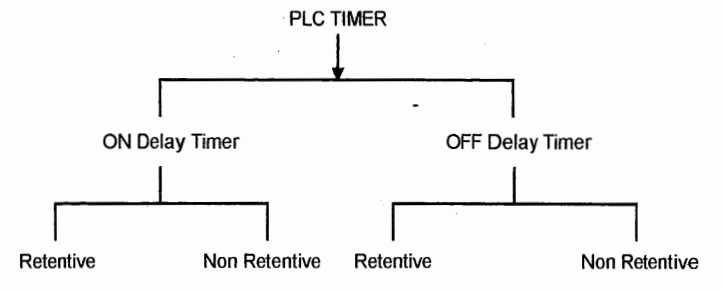

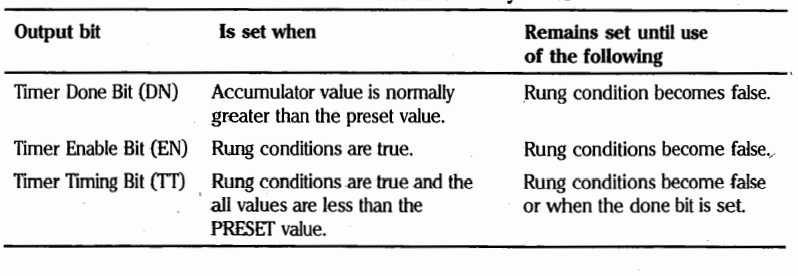

Timer ON-Delay

This instruction is used to delay turning an output on or off. The TON instruction begins to count time base intervals when the rung condition becomes true. As long as the rung condition remains true the timer increments its accumulator value, over each scan time until it reaches the preset value.

The Accumulator value is reset when the rung condition becomes false, regardless of whether the timer has timed out. The schematic diagram of such a timer is shown in fig and timer functions are shown in table

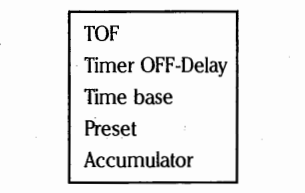

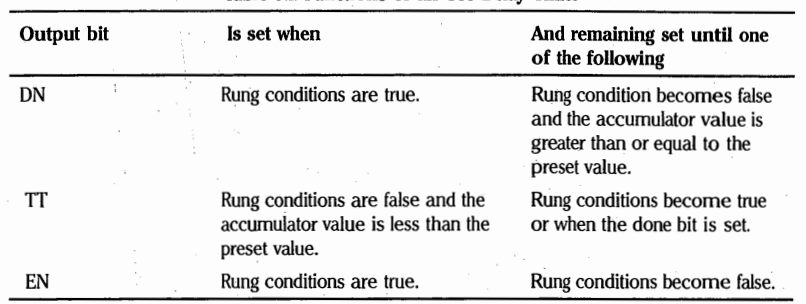

Timer OFF-Delay

This instruction is used to delay turning an output on or off. The TOF instruction begins to count time base intervals when the rung condition makes a true to false transition. As long as the rung condition remains false the timer increments its accumulator value over each scan until it reaches the preset value.

The Accumulator value is reset when the rung condition becomes false, regardless of whether the timer has timed out. The schematic diagram of such a timer is shown in fig and timer functions are shown in table

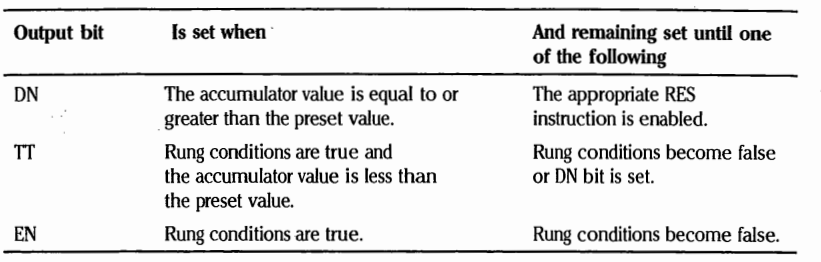

Retentive and Non-Retentive Timers

The Retentive Time (RTO) instruction is used to turn an output on or off after its timer has been on for a preset time interval. The RTO instruction is a retentive instruction that lets the timer stop and start without resetting the accumulated value. The RTO retains its accumulated value when any of the following occurs:

(i) The rung condition is false

(ii) The controller loses power

(iii) A fault occurs

To reset the retentive timer accumulated value and status bit after the RTO rung becomes false, a reset (RES) program is carried out. The timer function is shown in table

RESET (RES) – When the reset instruction is executed, it resets the data having the same address as the RES instruction.

Using Reset instruction,

Accumulator value is reset to 0

DN bit is reset

TT bit is reset

EN bit is reset

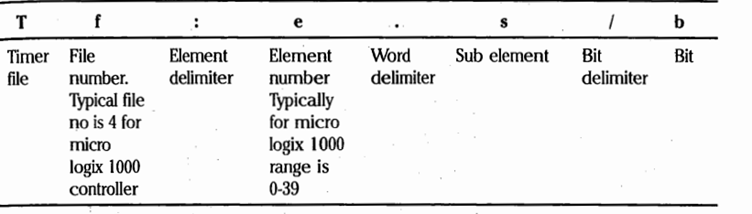

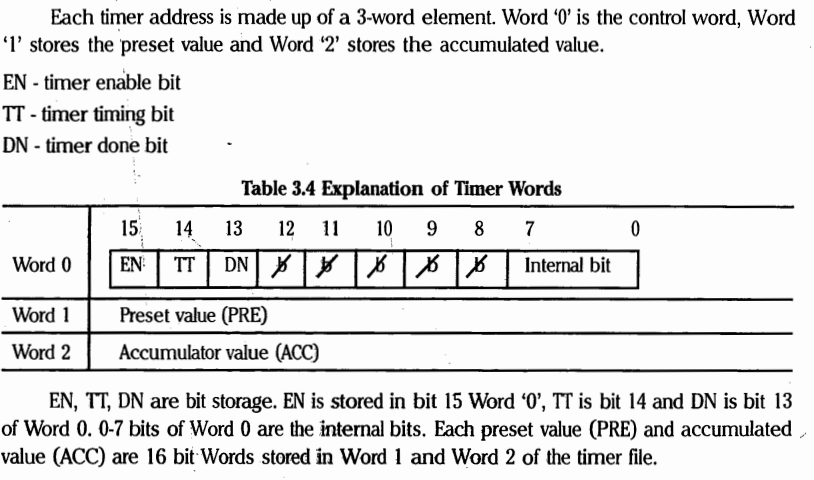

Format of Timer Instructions

Some examples of such instructions are as follows:

T4:0/15 or T4:0/EN – Enable bit

T4:0/13 or T4:0/DN – Done bit

T4:0/14 or T4:0/TT – Timer Timing bit

Function block mapping

Problems on Timer

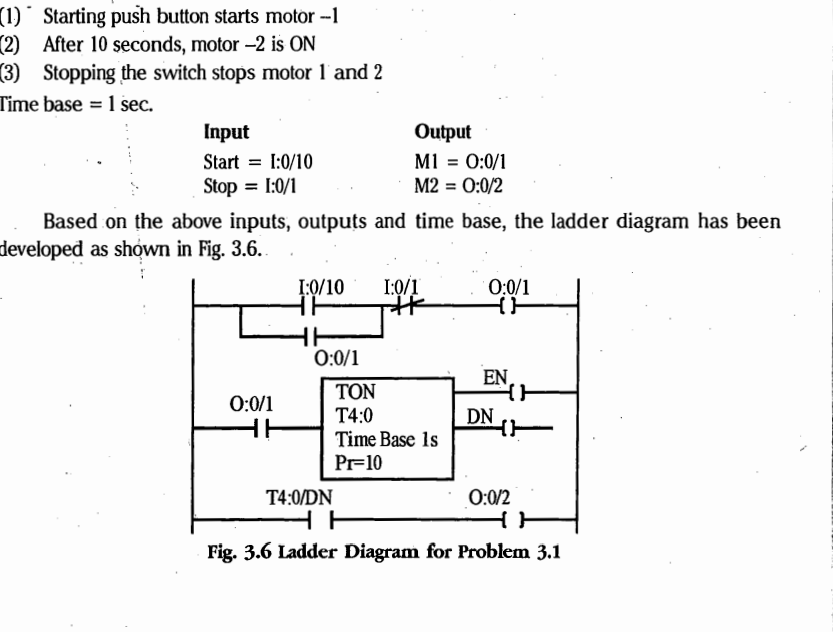

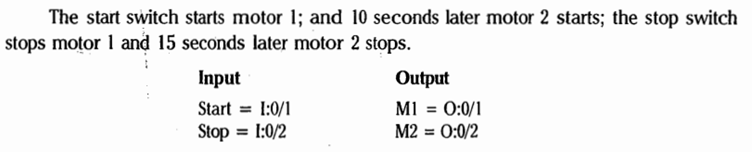

1) Draw a ladder diagram for a two motor system having the following conditions:

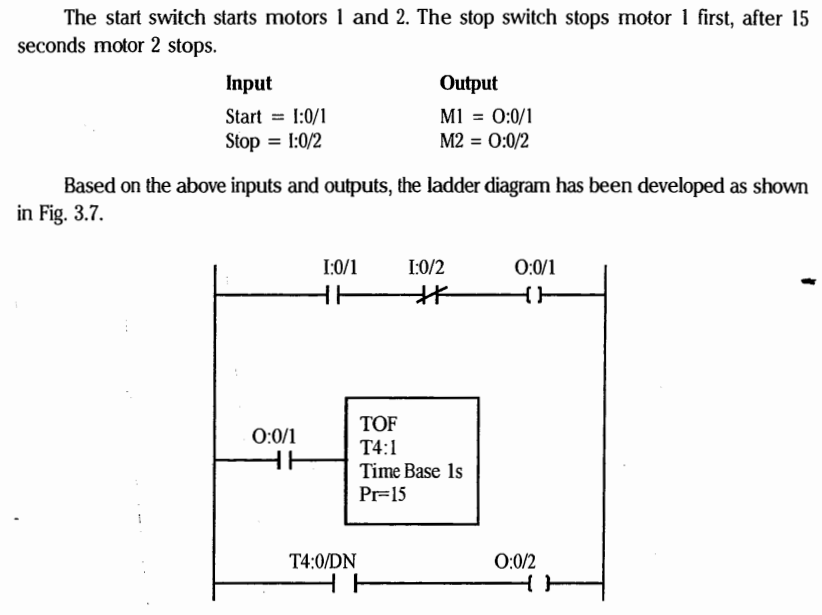

2) Draw a ladder diagram for a two motor system having the following conditions:

3) Draw a ladder diagram for a two motor system having the following conditions:

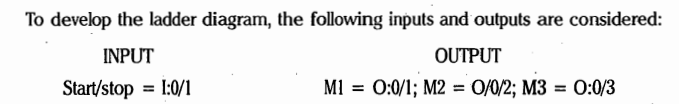

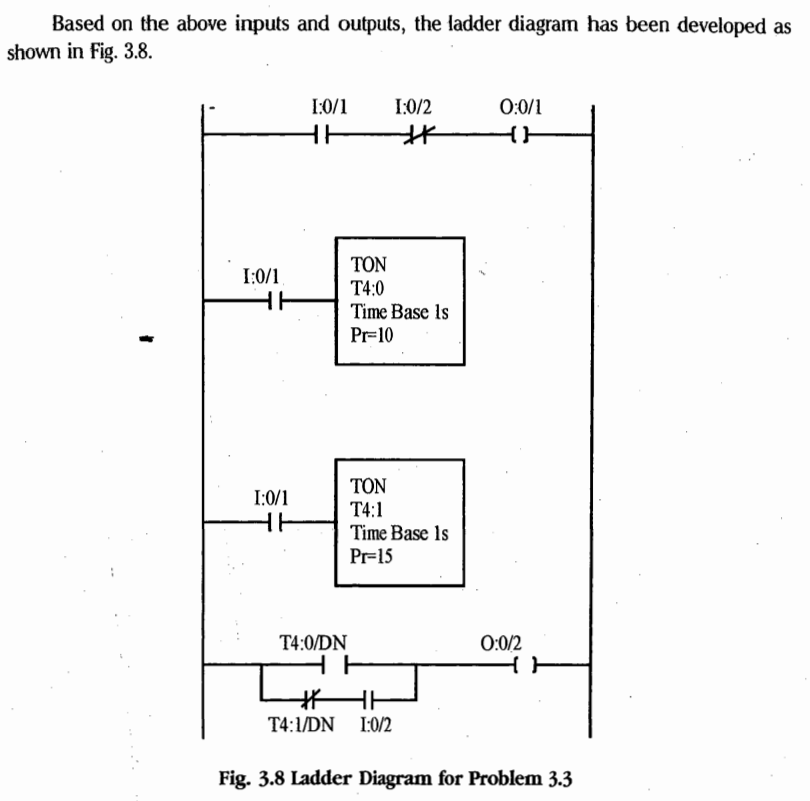

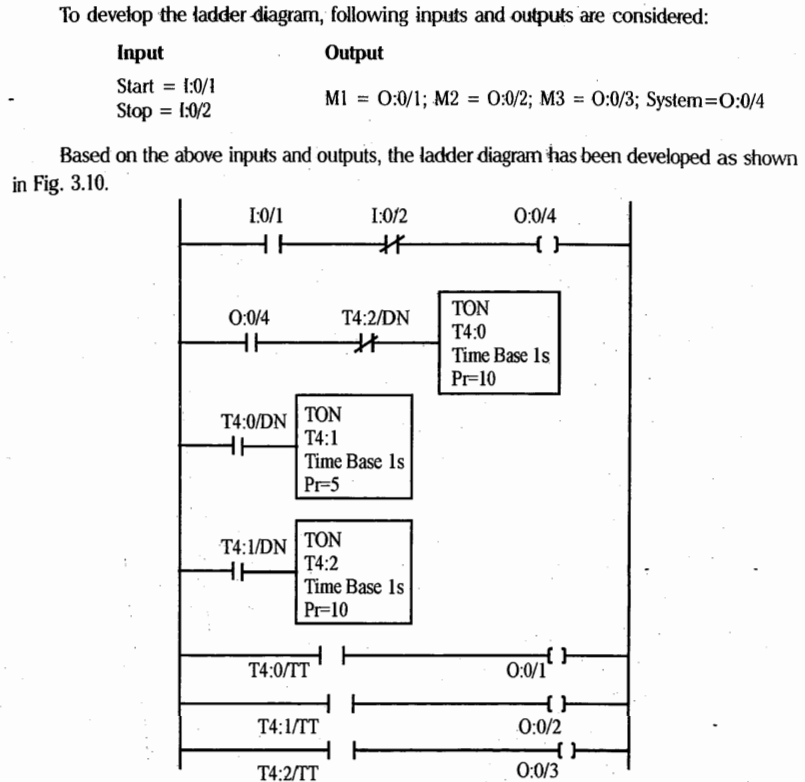

4) Draw a ladder diagram for a three motor system having the following conditions:

5) Draw a ladder diagram for a three motor system having the following conditions:

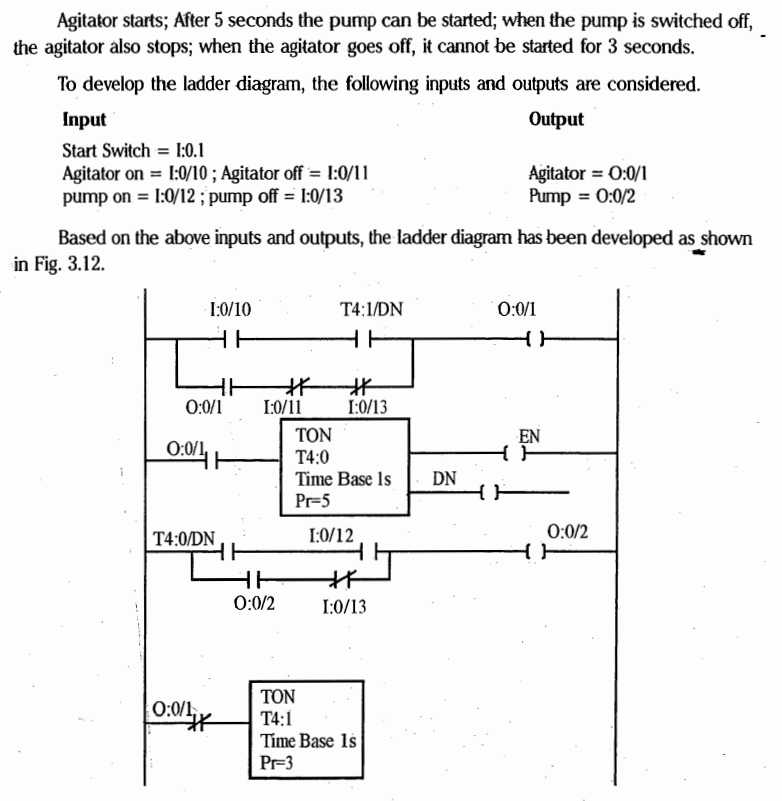

6) Draw a ladder diagram for an agiator-motor system having the following conditions:

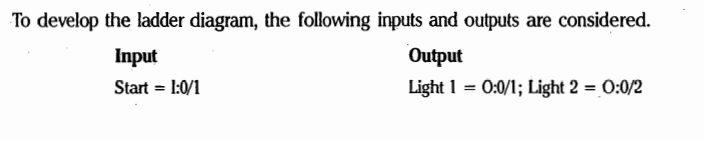

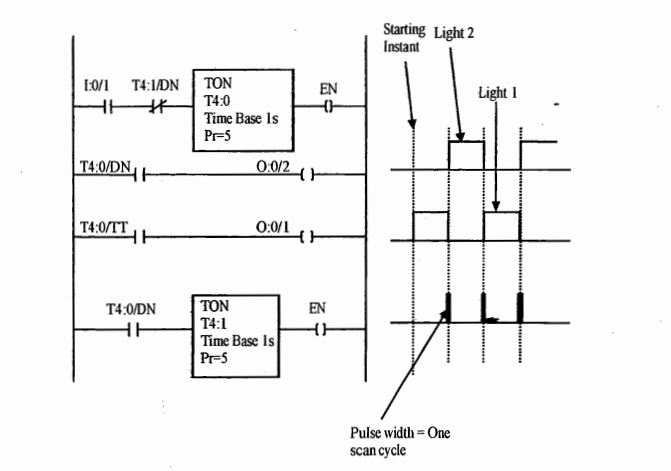

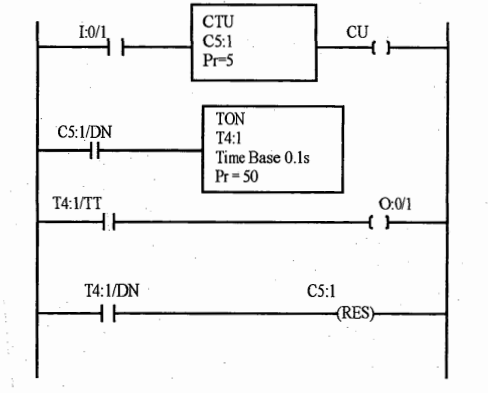

7) Blinking indicator lights are used quite extensively in industry. Design a circuit in which two lights are flashed alternatively every 5 seconds

Operation of a PLC Counter

The counter instructions operate in a similar manner to those of the timer instructions in the PLC. The major difference between the counter and the timer is that timer instruction will continually increment its accumulator value at a rate determined by the time base when the enable contact is on. On the other hand, the counter must see a complete contact transition from 0 to 1 each time it increments the accumulative value.

This means that the contact must return to its zero state before it can have a transition for a second time. In a counter, the contact can stay closed for any amount of time after a transition. What is important is that the transition has taken place

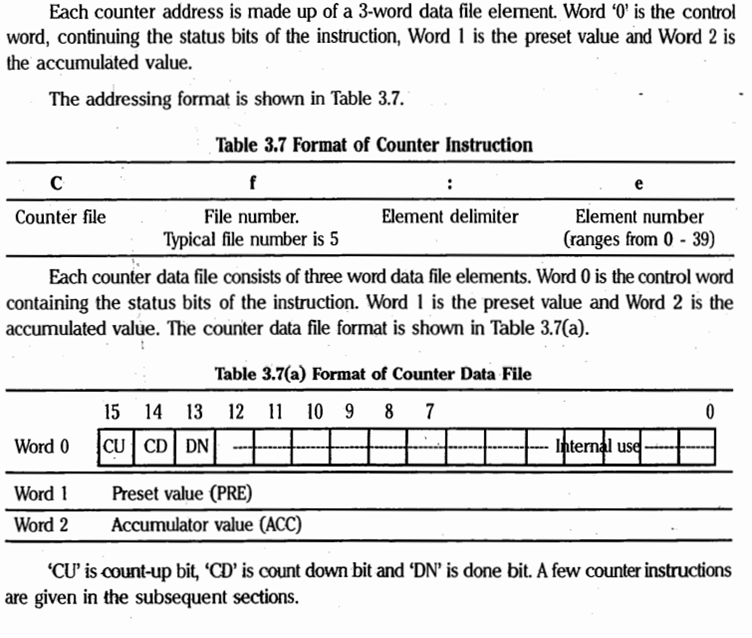

Counter Parameters

In general, a PLC counter has two parameters: `(a) The accumulator value (ACC) and (b) The Pre-set value (PRE)

(a) The accumulator value (ACC) is the number of false- to-true transition that have occurred since the counter was last reset.

(b) The preset valye (PRE) specifies the value that the counter must reach, before the controller sets the done bit. When the accumulator value becomes equal to or greater than the preset value, the done status bit is set. This can be used to control an output device.

Preset and accumulated values for counters range from -32,768 to +32,767 and are stored as signed integers. Negative values are stored as 2’s complement form

Overview of Counter Instructions

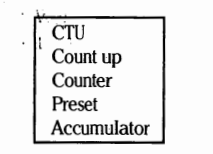

Count Up (CTU)

The CTU is an instruction that counts false-to-true rung transitions. Rung transitions can be caused by events occurring in the program( internal logic or by external field devices)

When the rung condition for a CTU instruction has made a false to true transition, the accumulated value is incremented by one count provided that, the rung containing the CTU instruction is evaluated between these transitions. The ability of the counter to detect a false to true transition depends on the speed of incoming signal. The on and off duration of an incoming signal must not be faster than the scan time.

The accumulated value is retained when the rung condition again becomes false. The accumulated count is retained until cleared by a reset (RES) instruction that has the same address as the counter reset.

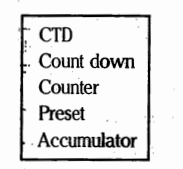

Count Down (CTD)

The CTD is a retentive output instruction that counts false-to-true rung transitions. Rung transitions can be caused by events occurring in the program (internal logic or by external field devices)

When the rung condition for a CTD instruction has made a false to true transition, the accumulated value is decremented by one count provided that, the rung containing the CTU instruction is evaluated between these transitions. The ability of the counter to detect a false to true transition depends on the speed of incoming signal. The on and off duration of an incoming signal must not be faster than the scan time.

The accumulated value is retained when the rung condition again becomes false. The accumulated count is retained until cleared by a reset (RES) instruction that has the same address as the counter reset.

Problems on Counter:

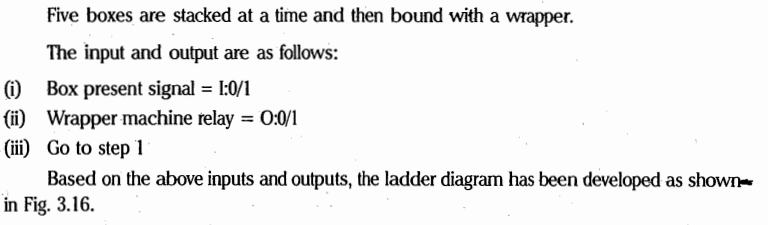

1) Draw a ladder diagram for a box packaging system having the following conditions.

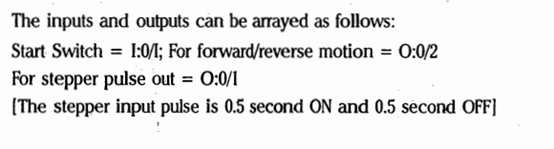

2) Design a ladder diagram that will control a stepper motor so that it moves 10 steps forward, waits for 20 seconds, and then cause the motor to move 10 steps in the reverse direction

Comparison Instructions

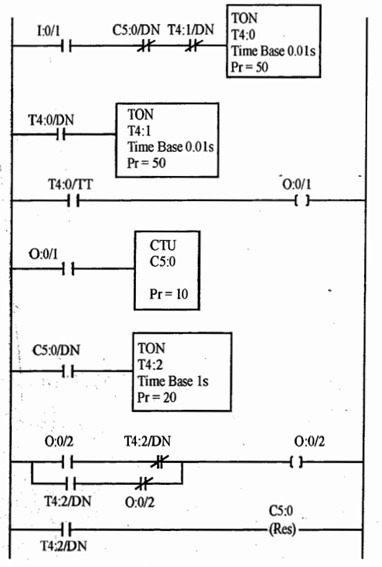

(i) “EQUAL” or “EQU” Instruction

The EQU instruction is used to test whether two values are equal. If source A and source B are equal, the instruction is logically true. If these values are not equal, the instruction is logically false. Source A must be Word Address. Source B can be either a Word Address or a constant. Negative integers are stored in 2’s complement form.

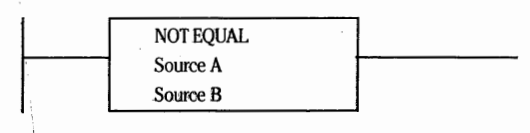

(ii) “ NOT EQUAL” or “NEQ” Instruction

The NEQ instruction is used to test whether two value are not equal. If source A and source B are not equal, the instruction is logically true. If two values are equal this instruction is logically false. Source A must be Word Address. Source B can be either a Word Address or a constant. Negative integers are stored in 2’s complement form.

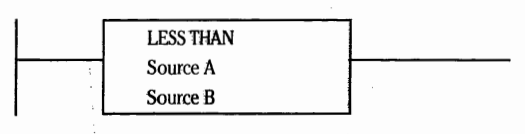

(iii) “LESS THAN” or “LES” Instruction

The LES instruction is used to test whether the value of source A is less than the value of source B. If this condition is fulfilled, the instruction is logically true, if the value at source A is greater than or equal to the value of source B, the instruction is logically false. Source A must be Word Address. Source B can be either a Word Address or a constant.

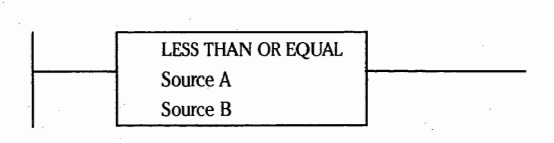

(iv) “LESS THAN OR EQUAL” or “LEQ” instruction

The LEQ instruction is used to test whether one value (Source A) is less than or equal to another (source B). if the value at source A is less than or equal to the value at source B, the instruction is logically true but if the former is greater than the latter, the instruction is logically false. Source A must be Word Address. Source B can be either a Word Address or a constant.

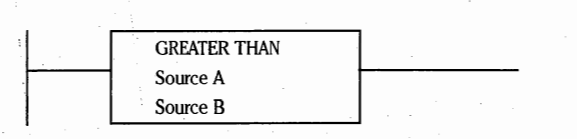

(v) “GREATER THAN” or “GRT” instruction

The GRT instruction is used to test whether one value (Source A) is greater than another (source B). If the value at source A is greater than the value at source B, the instruction is logically true but if the former is equal to or lesser than the latter, the instruction is logically false. Source A must be Word Address. Source B can be either a Word Address or a constant.

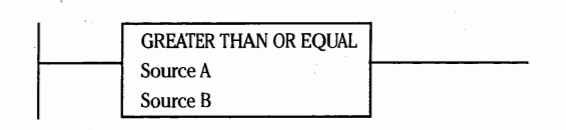

(vi) “GREATER THAN OR EQUAL TO” or “ GRQ” instruction

The GRQ instruction is used to test whether one value (Source A) is greater than or equal to another (source B). if the value at source A is greater than or equal to the value at source B, the instruction is logically true but if the former is less than the latter, the instruction is logically false. Source A must be Word Address. Source B can be either a Word Address or a constant.

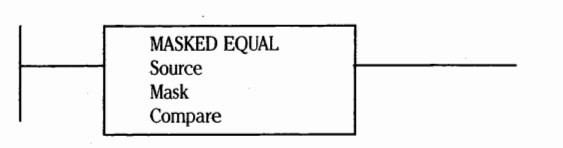

(vii) “MASKED COMPARISON FOR EQUAL” or “MEQ” Instruction

The MEQ instruction is used to compare data of the source address to data of the reference address. By using this instruction portions of the data can be masked by a separate word.

Source is the address of the value the user wants to compare. Mask is the address of the mask through which the instruction moves data. Mask can be a Hex value i.e. constant Compare is an integer value or address of reference

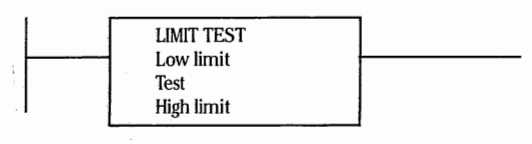

(viii) “LIMIT TEST” or “LIM” Instruction

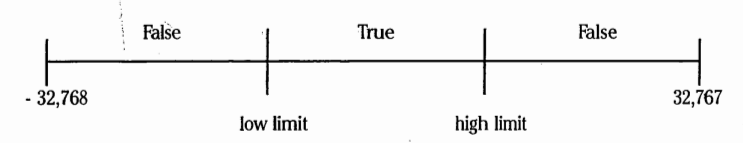

The LIM instruction is used to test whether certain values are within or outside a specified limit.

If the test value is equal to or greater than the low limit and equal to or less than the high limit, the instruction is true. The instruction is false if the test value is less than the low limit or higher than the high limit.

Problems

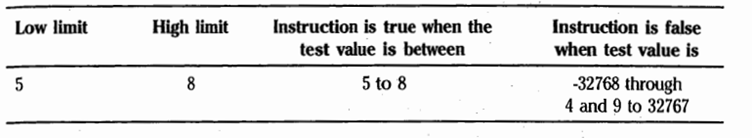

1) If the low limit is 5 and the high limit is 8, i.e low limit < high limit, tabulate the instruction status

The Instruction status has been shown in table below

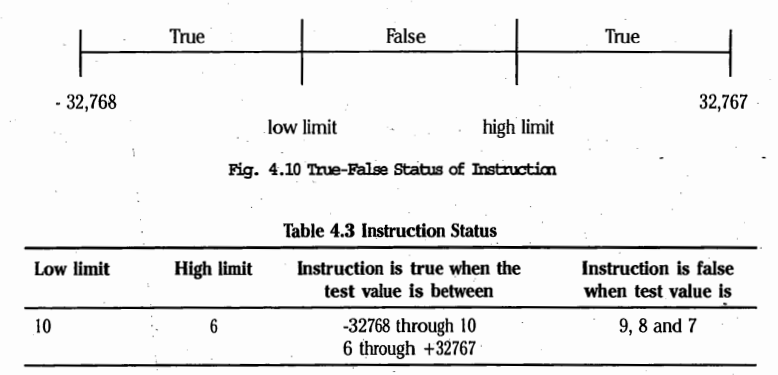

2) If the low limit is 10 and the high limit is 6, i.e, low limit > high limit, tabulate the instruction status

The condition is shown in fig and tabulated in table

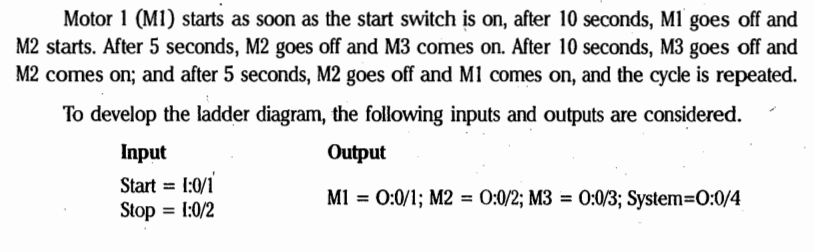

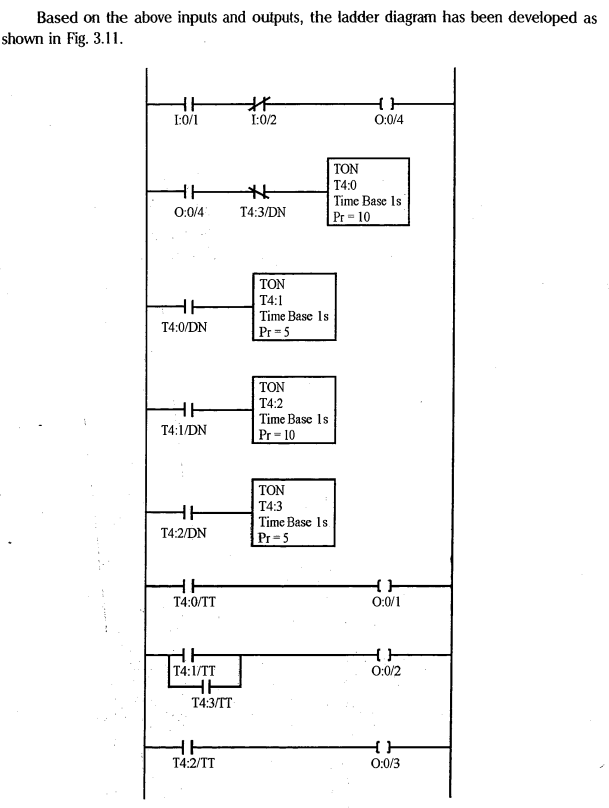

3) Motor 1 (M1) starts as soon as PLC Starts. After 10 seconds, motor 1 goes off and motor 2 starts. After 5 seconds, M2 goes off and M3 starts. After another 10 seconds, M2 restarts and after 5 seconds it stops, and M1 starts, and the cycle is repeated. Prepare the logic diagram for the process.